Basics of Control Systems Engineering

This course will help you understand engine system control requirements, basic architecture, and strategies used in the control system. You’ll become familiar with controls terminology and the development process that is used to meet engine system requirements, and develop an appreciation of transient behavior and dynamic coupling in an engine system.

- Engineers, managers, technical and program managers with backgrounds in systems, mechanical, electrical, or industrial engineering who are involved in vehicle powertrains, sensors/actuators, and diagnostics

- Test engineers and technicians

Engine Management Systems

- History

- Air-led

- Fuel-led

- Torque-led

- Development process overview

Control Theory Basics

- Goals

- Terminology

- Feedback (PID)

- Feed-forward (model and observer based)

- Discrete vs. continuous systems

- Performance considerations

Engine Management Basics

- System architecture

- Control design philosophies

- Combustion system control management

- Diagnostic and prognostic overview

Engine Control Functional Subsystems

- Gas-phase flow control (air system)

- Liquid-phase flow control (fuel system)

- Spark/Injection timing control

- Torque control

- Engine speed control

- Engine protection

Vehicle Control Subsystems

- Communications (TCM, HCM, BCM, etc.)

- After-treatment control

- Ancillary System control

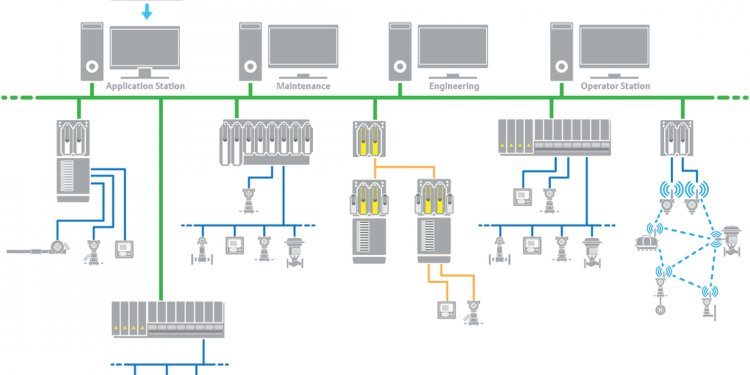

Controls Hardware/Software

- Embedded systems

- Control electronics, drivers, and devices

- PLCs, CAN, and communications

- Sensor/Actuator characterization

- A/D and D/A converters

- Digital signal conditioning

The Development Process

- Hardware

- Software

- Calibration

- Validation

- OBD II diagnostics/prognostics

- Tools

The Future

- Advanced/Low temperature combustion

- Cylinder pressure feedback

- Emissions sensing

- Online global optimization

Chi Binh La

Business Unit Director

Chi Binh has over 18 years of experience in engine development covering a broad range of topics including; NVH, Mechanical Development, Analysis and Simulation as well as Controls and Calibration. In 2012 he joined IAV where he is responsible for the strategic direction and profitability of the Gasoline and Alternative Fuels Engine business unit. Prior to joining IAV, he worked for Ricardo, Inc as director of Powertrain Development and Calibration. Chi Binh holds a Bachelor’s in Mechanical Engineering from University of Waterloo and a Master’s in Engine Systems from University of Wisconsin-Madison.

Michael Andrie is a Program Director, an Associate Researcher at the Engine Research Center (ERC) at the University of Wisconsin-Madison. He has more than 35 years of experience in engine development. Andrie began his engineering career at John Deere and then spent 17 years at Cummins Engine Company, where he managed and developed engines for the automotive, industrial, and marine markets. He joined the University of Wisconsin in 2007 and is active in research, mentoring, consulting, and continuing engineering education. Andrie holds several patents and is author on numerous publications. He also serves as the program manager for the over 30 members of the “Direct-injection Engine Research Consortium” (DERC) and the Biennial ERC symposium. Andrie holds a Bachelor’s and a Master’s in Agricultural and Mechanical Engineering from the University of Minnesota.

Blake Suhre is Manager of the Engine Control Systems at John Deere. He has over 20 years of experience in all aspects of engine systems and controls development. He was involved in the initial development of model-based controls for internal combustion engines and has experience applying these techniques to most combustion system types in use today. He was co-founder of the MotoTron Corporation and has held a variety of leadership roles in engine systems development and R&D. Suhre holds a Masters Degree in Mechanical Engineering from the University of Wisconsin-Madison.

Steve Fraser is a Technical Specialist at LHP Software LLC. He has worked over 25 years in a variety of industries including satellite and terrestrial communication systems, robotics, simulation modeling of large gas turbine power generation systems and Automotive and Heavy Duty applications. Fraser has worked with a variety of customers, primarily in the development of advanced controls and OBD diagnostics in the automotive industry. He worked on the development team of first generation diesel after-treatment control systems and diagnostics for the Diesel Particulate Filter (DPF), Nitrogen Adsorption Catalyst (NAC), and Selective Catalyst Reduction (SCR). Fraser has extensive experience in embedded software architecture design and test methodology using UML and AUTOSAR tools. He has a bachelor’s degree in Mechanical Engineering, a master’s degree in Applied Science, and a PhD in Mechanical Engineering from Concordia University in Montreal, Canada. He also has a bachelor of law degree from McGILL University in Montreal, Canada, specializing in intellectual property.