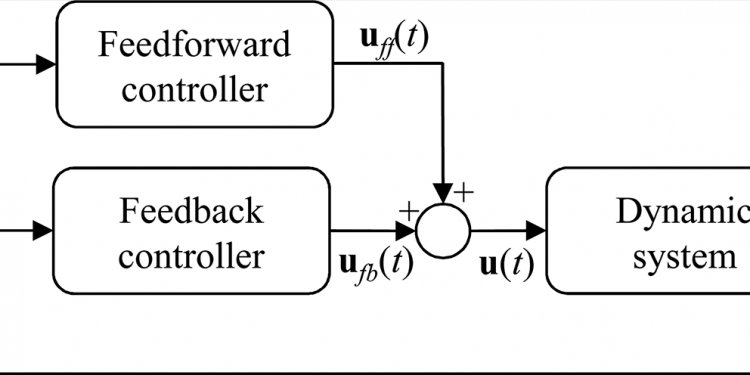

Feedforward control system example

In the business world, organizations constantly need to ensure that they're meeting the goals they've set for themselves. That's where the three types of organizational controls come in. Watch this lesson to learn about feedforward, concurrent and feedback controls.

Introduction

In this video, we will explore three organizational controls used in the controlling step of the management process: feedforward controls, concurrent controls and feedback controls.

To review, controlling is the fourth step of the management process. In this step, management develops measuring tools to use to determine whether organizational goals are being met. Management also compares data to measure for results and, if needed, takes corrective action.

There are several controls a manager can use to affect change and fluctuations in the goals for the organization. Since problems can occur at any time during a process, it is important to have a few different ways to manage issues. A manager's toolbox should be equipped with three types of controls: feedforward controls, concurrent controls and feedback controls.

Controls can focus on issues before, during or after a process. The best way to understand the three different types of organizational controls is to think about the controls as before, during and after decisions made by managers.

Feedforward Controls Explained

Feedforward controls involve identifying and preventing problems in an organization before they occur. Feedforward controls are proactive and preventative. Feedforward controls are helpful to managers because they allow a manager to plan work effectively; they can regulate resources like employees, raw materials and capital ahead of time. This means that future problems can be avoided. Although feedforward controls can be costly and can slow down the planning process, they help to avoid problems later on.

Let's imagine the emergency room at City Hospital. The emergency room requires many different employees to properly treat patients. From highly-skilled to minimally-skilled employees, each function of the emergency room must be fully operational and run smoothly.

In order to avoid problems that may occur in the emergency room, it is important that City Hospital management hire the right people, inspect and test equipment regularly and have enough capital resources to manage any medical emergency that may come their way. This is a focus on inputs, or things the organization can put into the planning to be sure objectives can be met.

A closer look at the members of the management team of the emergency room will reveal that feedforward controls are always in action. As we look at examples of feedforward controls, we will find that a very detailed human resource plan, an equipment maintenance plan and a well-funded budget plan are in place.

Feedforward control planning can be used in planning for the Human Resource Department. A human resource plan ensures that the hiring managers are hiring the right people for every position. However, there is a downside. Hiring the right people can be costly and time consuming. Time and money is spent on placing Help Wanted ads in the right newspapers and right online job sites, interviewing candidates, running background checks and drug testing, training and health benefits.

Without a strong human resource plan, the emergency room may not be appropriately staffed. There may not be enough medical staff to run the emergency room. This can cause a myriad of problems later on.

Here are some examples of how a proactive and preventative approach can help to avoid problems later on:

- Thoroughly interviewing a candidate can tell a human resource manager much about how this person would fit into the organization. A rushed interview may result in hiring the wrong person for the job.

- Running background checks and drug testing employees is very important. An emergency room is no place for employees with criminal backgrounds or drug problems. For example, hiring a drug user can result in patient medication discrepancies, employee accidents and injuries, higher liability claims and absenteeism.

- Training programs are effective in maintaining quality standards. There are so many things that can go wrong in an emergency room. For example, slips and falls can be avoided by training employees how to clean up a spill.

- Another feedforward control might be offering employees a good plan. When employees are healthy, they reliably come to work. This cuts down on absenteeism.

Concurrent Controls Explained

Concurrent controls involve identifying and preventing problems in an organization as they occur. This means that systems are monitored in real time. Concurrent controls begin with standards and all employee activity is measured against the standard. Usually these include quality control standards. This means that products and services can be checked as they are being produced or performed to be sure that the highest quality product or service is being produced or provided. Concurrent controls are important because they occur in real time.

This is a focus on ongoing processes, or things the organization can change in real time to be sure the objectives can be met.

Let's pay another visit to City Hospital. The emergency room at City Hospital uses concurrent controls when decisions simply cannot be made based on a preventative approach. Some problems arise during an activity. So, rather than wait until the entire work activity is completed, concurrent controls allow managers to monitor work activities as they occur. Some of the areas of an organization that benefit from concurrent controls are production and employee behavior.

Here are some examples of how a real-time approach can help to detect problems as the activity is being performed:

City Hospital employs thousands of people who perform many different jobs. One of the busiest places in City Hospital is in the cafeteria. On any given day or night, the staff of the cafeteria serves over 5, 000 meals. Meals are prepared on an assembly line in the kitchen and then delivered to rooms. The meals are prepared on an assembly line, meaning trays flow down a conveyor belt. As the trays pass through various stations, components of the meal are placed on the tray.

The conveyor belt is equipped with cameras and sensors that detect problems along the way. Cameras will show a watching quality control manager how the belt is moving along at any given time. The sensors sound an alarm if the belt should stop or become too overloaded with trays. When something goes wrong on the assembly line, the quality control manager is notified immediately. Upon learning of an issue, the manager can make decisions immediately and in real time.

An organization that upholds high quality standards will generally have employees who uphold the same quality standards. Concurrent controls allow for employees to evaluate their work as they are performing the job to determine whether changes need to be made.

If a meatball or two find their way to the assembly line that do not meet the standard, the employee responsible for the meatball will be immediately notified to make changes to the procedure or the recipe to meet the standard. The corrective action taken during this step will avoid problems after the fact.

Unlock Content

Over 30, 000 lessons in all major subjectsGet FREE access for 5 days,

just create an account.

No obligation, cancel anytime.

Want to learn more?